Few of the key features of this system are the use of unique foam concept for folding purposes and also the ability of cutting system to cut “cross” shapes.

Using a foam simplifies the folding process by taking advantage of the material property of foam. The first highlight of our system is the foam folding subsystem. If enough force is pressed between the object and the foam, foam will deform and adapt to the shape of the object. The idea was based on an observation that when an object is submerged into a liquid, the object displaces the liquid and hence one is end with an object surrounded by liquid. Nevertheless, the key difference is that foam also presents enough resistance, so that it can deform weak materials in this case paper while it adapts to the shape of stiffer materials in this case the box itself.

The second highlight of the system is capability of cutting paper into cross shaped. Wrapping paper is cut into cross shape to cover the six sides of the box with no excess paper.

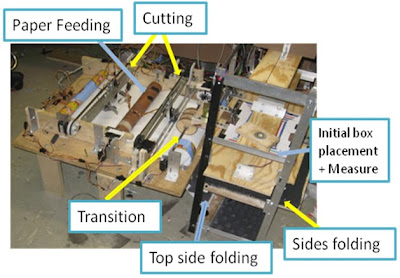

System Overview

Figure 1. System Overview

Operation Process:

1. User puts the box at the measurement platform

2. Paper is rolled out and cut into cross or rectangle shaped

3. Transit cut paper to folding subsystem

4. Box gets pushed through foam, fold bottom and sides of box

5. Foam door rotates down and fold top side of box

1. User puts the box at the measurement platform

2. Paper is rolled out and cut into cross or rectangle shaped

3. Transit cut paper to folding subsystem

4. Box gets pushed through foam, fold bottom and sides of box

5. Foam door rotates down and fold top side of box

Subsystems

1. Measuring: The user places a random sized box (within the dimensions) at the center of the area that has colored coded lines to align the box. Then, two IR sensors measure box’s width and length.

Figure 2. Measuring System

2. Cutting: Gift Wrap paper is rolled out and cut into a rectangle or cross shape according to the dimensions of the box measured from step one.

Figure 3. Cutting System

3. Transition: Mechanism of wheels transfers cut paper from cutting subsystem to folding subsystem.

Figure 4. Feeding System

4. Gluing: Glue is sprayed on top of the cut paper, which lays one level below the measuring system that is holding the box on top.

Figure 5. Gluing System

5. Folding:The Box, which has the cut paper underneath, is pushed down through a layer of thick foam, so the four lateral sides of the box and bottom are glue and wrapped around it. Top side folding: A door rotates down 90 degrees to push the remaining paper onto the top of box to finalize the wrap.

Figure 6. Folding System

Team's Responsibility

Siying(Diana) Hu / Electronics and Control

Zhiwei(Hank) Huang / Mechanics

Chenyue(Melody) Li / Electronics and Control

Mohitdeep Singh / Mechanics

Mohitdeep Singh / Mechanics

Video

No comments:

Post a Comment